In today’s competitive industrial world, protecting valuable metal components from corrosion is a top priority. One of the most effective solutions for this challenge is VCI Film (Volatile Corrosion Inhibitor Film). Widely used in packaging across industries, VCI film not only ensures protection against rust but also provides an recyclable, cost-efficient, and easy-to-use packaging method.

What is VCI Film?

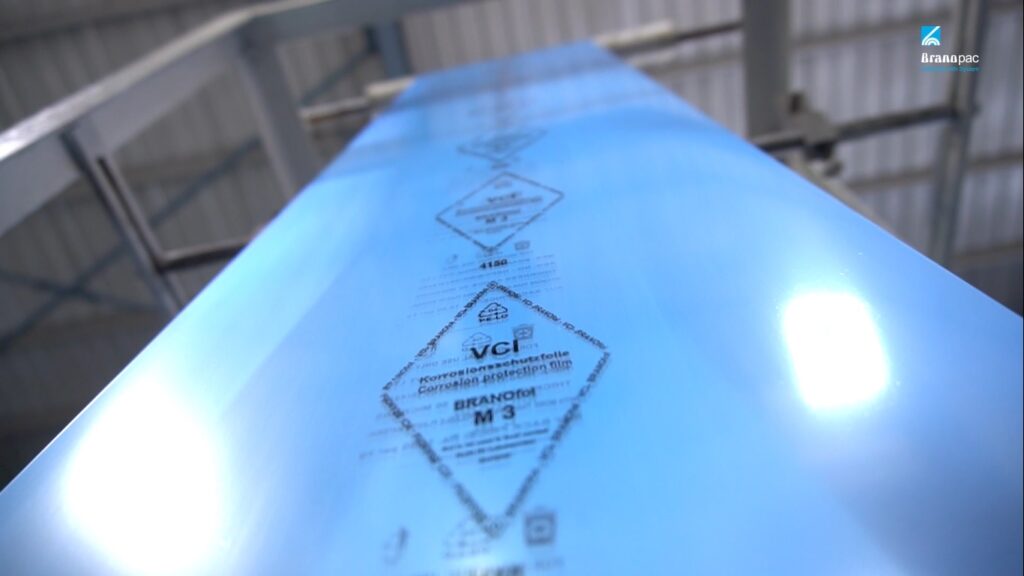

VCI Film is a specially engineered plastic packaging material infused with volatile corrosion inhibitors. When metal parts are wrapped or sealed inside the film, the VCI molecules vaporize and settle on the metal surface, forming an invisible protective layer. This layer prevents moisture, oxygen, and other corrosive elements from reacting with the metal.

Key Uses of VCI Film

- Automotive Industry

Automobile manufacturers and suppliers use VCI film to package engine parts, gears, bearings, fasteners, and sheet metals. It ensures that the components remain rust-free during storage and transportation, even across humid or coastal regions.

- Export Packaging

When metal goods are exported overseas, they are exposed to varying temperatures, condensation, and salt-laden air. VCI films provide reliable protection, making them ideal for export shipments of machinery, steel coils, tools, and spare parts.

- Heavy Engineering & Machinery

Large equipment and heavy machinery often need long-term storage before being commissioned. Wrapping them with VCI film ensures that critical metal surfaces remain corrosion-free, avoiding costly repairs and downtime.

- Electronics & Electrical Components

Copper, aluminum, and other sensitive electronic components are prone to oxidation. VCI film protects cables, circuit boards, and connectors from corrosion while keeping the packaging lightweight and easy to handle.

- Military & Defense Applications

In defense and aerospace industries, corrosion-free equipment is critical. VCI films are used to store and transport weapons, aircraft parts, and communication systems, ensuring reliability under harsh conditions.

- Steel & Metal Fabrication Industry

Steel coils, sheets, and fabricated metal parts are highly susceptible to rusting. VCI films are widely used for bulk packaging of steel products, ensuring they reach customers in perfect condition.

- Long-Term Storage

Industries with seasonal demand or surplus inventory rely on VCI films for long-duration storage of metal goods. The film ensures extended protection without the need for applying messy oils or greases.

Benefits of Using VCI Paper for Metal Protection

-

- ✅ Clean, dry, and oil-free protection

-

- ✅ Cost-effective and easy to use

-

- ✅ No cleaning required before use

-

- ✅ Suitable for ferrous and non-ferrous metals

-

- ✅ Eco-friendly and recyclable options available

-

- ✅ Ideal for export packaging and long-term storage

Benefits of Using VCI Film

- Clean & Dry Protection – No need for oils, wax, or grease.

- Eco-Friendly – Many VCI films are recyclable and non-toxic.

- Time-Saving – Eliminates extra cleaning before use.

- Cost-Effective – Reduces rework, rejection, and damage costs.

- Versatile – Suitable for small parts, large machines, and even bulk shipments.

Final Thoughts

VCI Film has become an indispensable part of modern industrial packaging. Its versatility, reliability, and ease of use make it the go-to solution for protecting metals against corrosion. Whether you are in automotive, engineering, electronics, or export, incorporating VCI film in your packaging strategy ensures that your products remain rust-free and ready to perform.